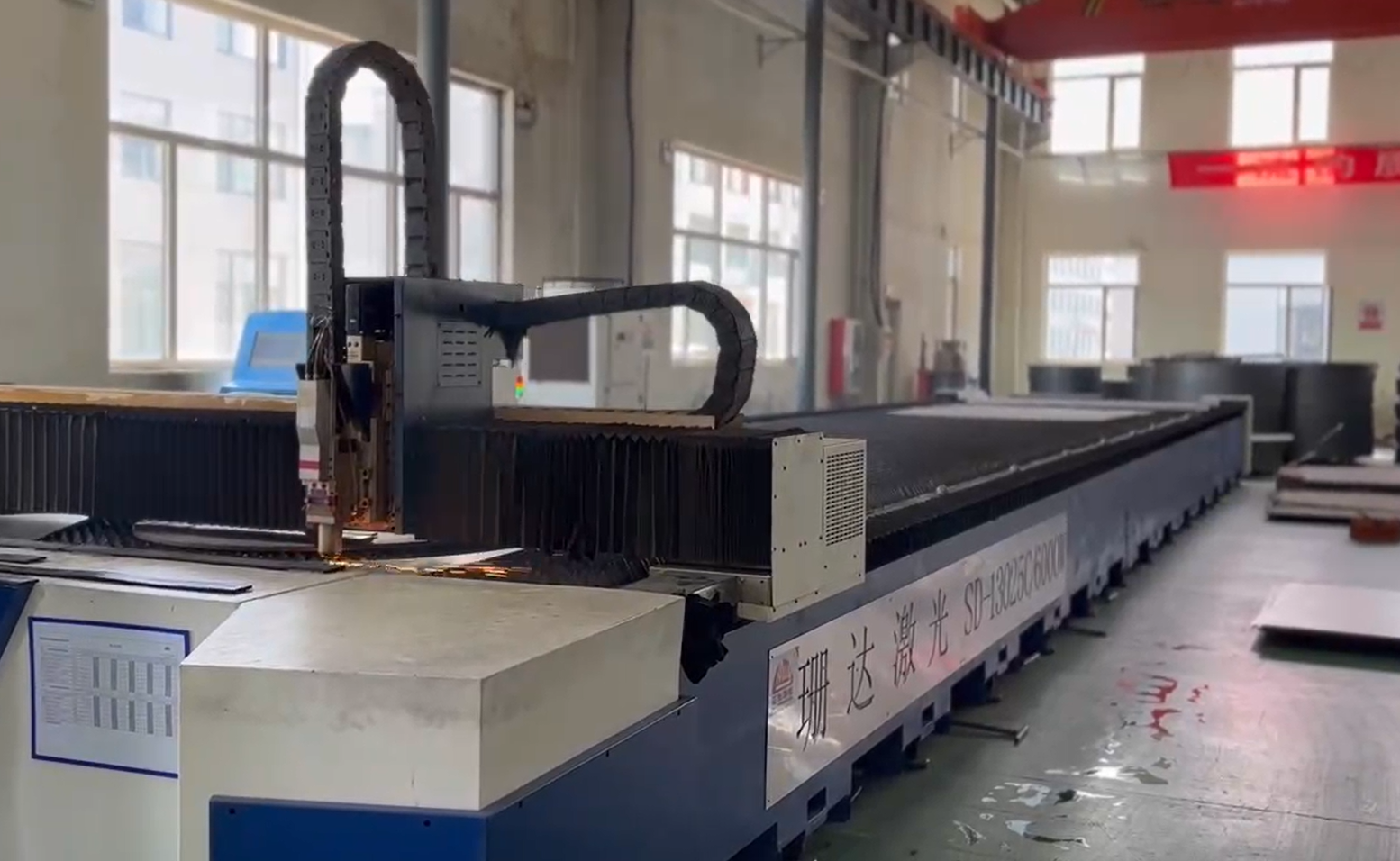

Covering an area of 5,500 square meters, the facility is equipped with modern CNC machining equipment, including gantry milling and boring centers, vertical CNC lathes, laser welding machines, and laser cutting machines. The facility has the capacity to produce 150 sets of electrolyzers annually, with sizes ranging from 50 Nm3/h to 1,500 Nm³/h, supporting an overall production capacity of 1 GW.

The electrolyzer machining and assembly center is located in Wuqing District, Tianjin, and is operated by Ally Hydroqueen Energy Equipment Co., Ltd., a subsidiary of Ally Hydrogen Energy.

learn more

Accuracy and Performance

Accuracy and PerformanceIntelligent Control: Real-time monitoring and fault diagnosis functions during machining ensure stability throughout the production process.

Intelligent Fixtures: Intelligent, flexible fixtures ensure precise positioning and machining during the process, guaranteeing consistency and interchangeability in mass production for every piece produced.

Processing capability

Processing capabilityProcessing Range: Capable of handling pieces with a diameter of up to 2,500 mm (such as bipolar plates), suitable for the machining needs of large components like electrolyzers.

Capacity: Approximately 1,200 bipolar plates can be processed per month (for 1,000 Nm³ electrolyzers).

Characteristic

Technical characteristicsFlow Channel Simulation: Flow channel design is optimized through simulation to enhance efficiency.

Gasket Structure Simulation: New polymer materials are used based on simulation to ensure the sealing integrity of the electrolyzer.

Proprietary Process Technology: The separation and cooling processes are highly integrated, minimizing space requirements and ensuring a compact equipment layout.

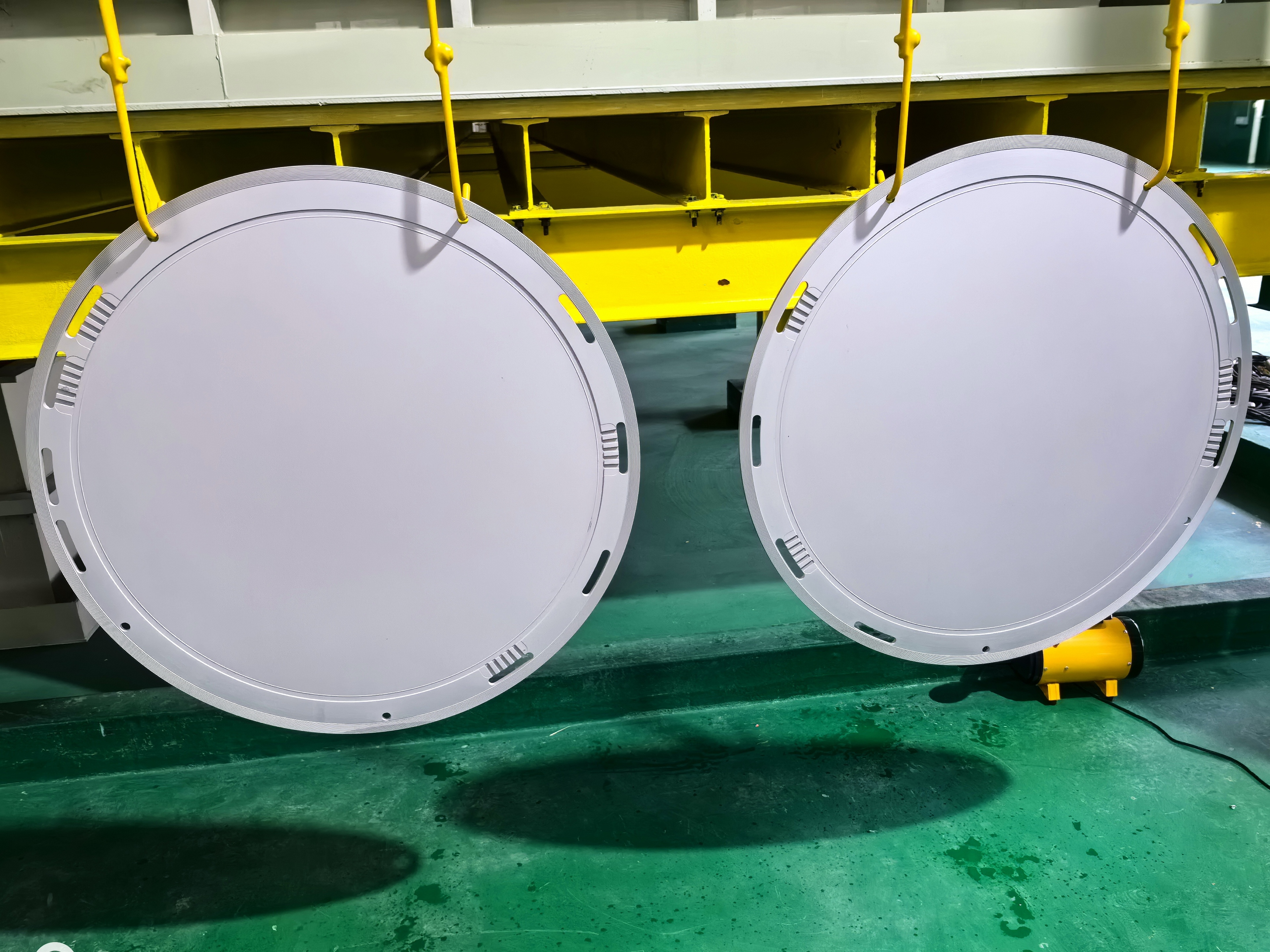

Two fully automated electroplating production lines are employed, with unique technologies and extensive experience in raw material processing, electroplating solution preparation, current curve control, plating consistency, and inspection. The center has comprehensive quality testing and analysis capabilities, including coating thickness, adhesion strength, blue dot testing, and bath solution analysis.

The electroplating and electrode production center is located in Qing Shen, Sichuan, the only surface treatment park in the southwest, and is managed by Ally Hydrogen’s strategic partner, Sichuan Liancai Metal Surface Treatment Co., Ltd., which has over 20 years of experience in electroplating technology.

learn more

Testing methods

Testing methodsCoating Density: Pore density testing of the coating is performed according to QB/T3823-1999.

Coating Adhesion: Adheres to GB5933-86, using the bending test in sections 2.1.1 and 2.1.2 to ensure the coating does not peel or fall off, meeting national standards.

Coating Thickness: Advanced techniques are used to measure the coating thickness, with a variance of ≤1.5 microns between the recessed and flat areas over a 1 mm² surface.

Production Monitoring: Electroplating solutions are monitored daily using specific methods to ensure the stability of the electroplating process.

Processing capability

Processing capabilityProcessing Scope: Specializes in electroplating for electrolyzer bipolar plates and producing electrodes for alkaline electrolyzers.

Production Capacity: Can process approximately 3,000 bipolar plates (up to 2,800 mm in diameter) and over 3,000 catalytic electrodes per month.

Characteristic

Technical characteristics1. Bipolar Plate Electroplating:

- Utilizes a unique electroplating solution formula and automated control to ensure a denser and more uniform coating.

- Scientific process management ensures quality control and measurement at each stage.

- Advanced detection methods are employed to guarantee the quality of the bipolar plates.

2. Electrode Preparation Process:

- Multicomponent alloy catalytic layers are prepared using the electrodeposition method, ensuring higher stability.

- Special surface treatment techniques enhance the bonding strength of the catalytic layer, eliminating the need for activation, reducing costs, and improving electrode stability and resistance to "reverse current" impacts.

The purification system for water electrolysis hydrogen production is designed to remove trace impurities from hydrogen and oxygen, ensuring the quality of these gases meets user requirements. The system consists of two main parts: deoxidation and temperature swing adsorption (TSA), and dehydrogenation and TSA. It employs a patented three-tower lossless drying process with composite bed packing in the adsorption towers. The system operates at lower regeneration temperatures, saving over 20% in electricity consumption, and can handle gas volumes ranging from 20 to 50,000 Nm³/h, making it particularly suitable for "multi-to-one" cluster electrolyzers.

learn more

Technical advantages

Technical advantagesProprietary Process: The separation and cooling processes are highly integrated, minimizing space requirements and ensuring a compact equipment layout.

High Automation: The system can operate without onsite supervision, with flexible load adjustment between 30%-110% flow, ensuring safe and stable operation while meeting technical requirements.

System Scale: 50 to 2,000 Nm³/h.

### Purification System Advantages:

High-Efficiency Deoxidation: Utilizes a self-developed high-efficiency noble metal catalyst with single-atom surface activation technology, which has a low activation temperature.

Temperature Resistance: The catalyst can withstand thermal shocks up to 450°C, making it suitable for handling oxygen fluctuations in flexible water electrolysis hydrogen production.

Deep Deoxidation: The composite bed formula technology ensures a high degree of oxygen removal.

Patent-Protected Purification: The system allows for hydrogen recovery rates up to 100% with zero hydrogen loss, and energy consumption is reduced by over 20%.

Wide Load Range: The system operates effectively within a 10% to 120% load range.

Dedicated Heater Design: Separately configured heaters avoid redundancy in key equipment, reducing investment costs. The heaters offer continuous, stable operation and extended service life.

Three-Tower Switching Process: The unique three-tower switching technology recycles the residual heat from the drying tower regeneration process, improving regeneration efficiency.

Low-Temperature Regeneration: Micro-heat regeneration technology operates at temperatures below 200°C, 50°C lower than traditional systems (which regenerate at 250°C), reducing energy consumption by more than 20%.

A hydrogen energy engineering company with 24 years of chemical industry expertise, providing over 700 hydrogen, ammonia, and methanol systems. The company has a team of highly experienced engineers in various disciplines, including process, electrical, instrumentation and control, equipment, and after-sales service. They offer a range of services including catalyst and adsorbent development, electrolyzer development, engineering design, equipment manufacturing, installation and commissioning, operation and maintenance, and sales of hydrogen, ammonia, and methanol.

learn more

service features

service featuresCustomized O&M Services: Tailored operation and maintenance services based on the specific needs of hydrogen production, ammonia synthesis, methanol production, and hydrogen refueling station customers. This includes but is not limited to equipment upgrades, process optimization, energy efficiency improvements, operational planning, and maintenance and repair services.

One-Stop Service: Provides 24/7 technical support, including training and product sales, ensuring continuous service and support.