The company has rich experience in the research, development and application of catalysts and adsorbents, providing technical parameters for engineering projects, screening qualified suppliers at home and abroad, and testing the quality of adsorbents used in the project to ensure the project quality. Three editions of the Application Manual of Industrial Adsorbents have been published, covering the static and dynamic adsorption performance curves of about hundreds of adsorbents in five major categories of nearly 100 enterprises at home and abroad. Special research and development have been carried out for adsorbents and catalysts in special fields, and major breakthroughs have been made in the technologies of catalysts such as high-efficiency copper catalysts for methanol hydrogen production, wide-temperature chrome-free medium-shift catalysts, high-efficiency copper adsorbents for CO, and a number of technologies have reached the international advanced level.

learn more

Index

Main performance indicators催化剂名称 | 吸附剂名称 |

天然气转化制H2催化剂 | PSA专用活性氧化铝 |

甲醇转化制H2催化剂 | PSA专用活性炭 |

甲醇直接转化制H2催化剂 | PSA专用硅胶 |

甲醇合成催化剂 | PSA专用分子筛 |

中温变换催化剂 | PSA专用CO吸附剂 |

J641-AL series valves are special pneumatic valves designed and manufactured according to the technical requirements of High-Performance Pneumatic Globe Valves in the domestic PSA hydrogen extraction unit and national standards, including normal temperature type and high temperature type; The program-controlled valve has small volume, light weight, fast action, good sealing performance, long service life and high reliability.

learn more

Characteristic

Technical characteristicsJ641 – AL series valves are special pneumatic valves designed and manufactured according to the technical requirements of High-Performance Pneumatic Globe Valves in the domestic PSA hydrogen extraction unit and national standards, including normal temperature type and high temperature type; The program-controlled valve has small volume, light weight, fast action, good sealing performance, long service life and high reliability.

Purpose: It is mainly used in various pressure swing or temperature swing adsorption gas separation devices and various industrial fluid transmission occasions requiring frequent switching.

Index

Main performance indicatorsTechnical parameters (normal temperature type) | |

Nominal pressure and diameter | PN≤6.4Mpa, DN<200mm |

Nominal pressure and diameter | PN≤4.0Mpa, DN<500mm |

Applicable temperature | -20~120℃ |

Applicable medium gas | Gas:natural gas, air, O2, N2, H2, CO2, CO, etc; Liquid: water; steam; oil; |

The maximum working pressure difference | 3.0MPa or as required by the user |

Actuator driving pressure air pressure | 0.4~0.6MPa (G); Hydraulic pressure: 3~8MPa (G) |

Application

application areaIt is mainly used in various pressure swing adsorption or temperature swing adsorption gas separation devices, as well as various industrial fluid transmission occasions requiring frequent switching.

Material

MaterialValve body: WCB or stainless steel

Valve rod: 2Cr13 or 40Cr or 1Cr18Ni9Ti, 45

Valve core: carbon steel-composite engineering material

Valve seat: 1Cr18Ni9Ti, 316

Standard

StandardFlange standard:

GB/T 9113.1-2000 Flat and Raised Face Integral Steel Pipe Flanges

GB/T 9113.2-2000 Integral Steel Pipe Flanges with Raised Face

The sealing surface of the valve body is concave (FM), which can be used with JB, HG and other flange standard convex flanges.

Parts material and flange standards can be customized according to the special requirements of users.

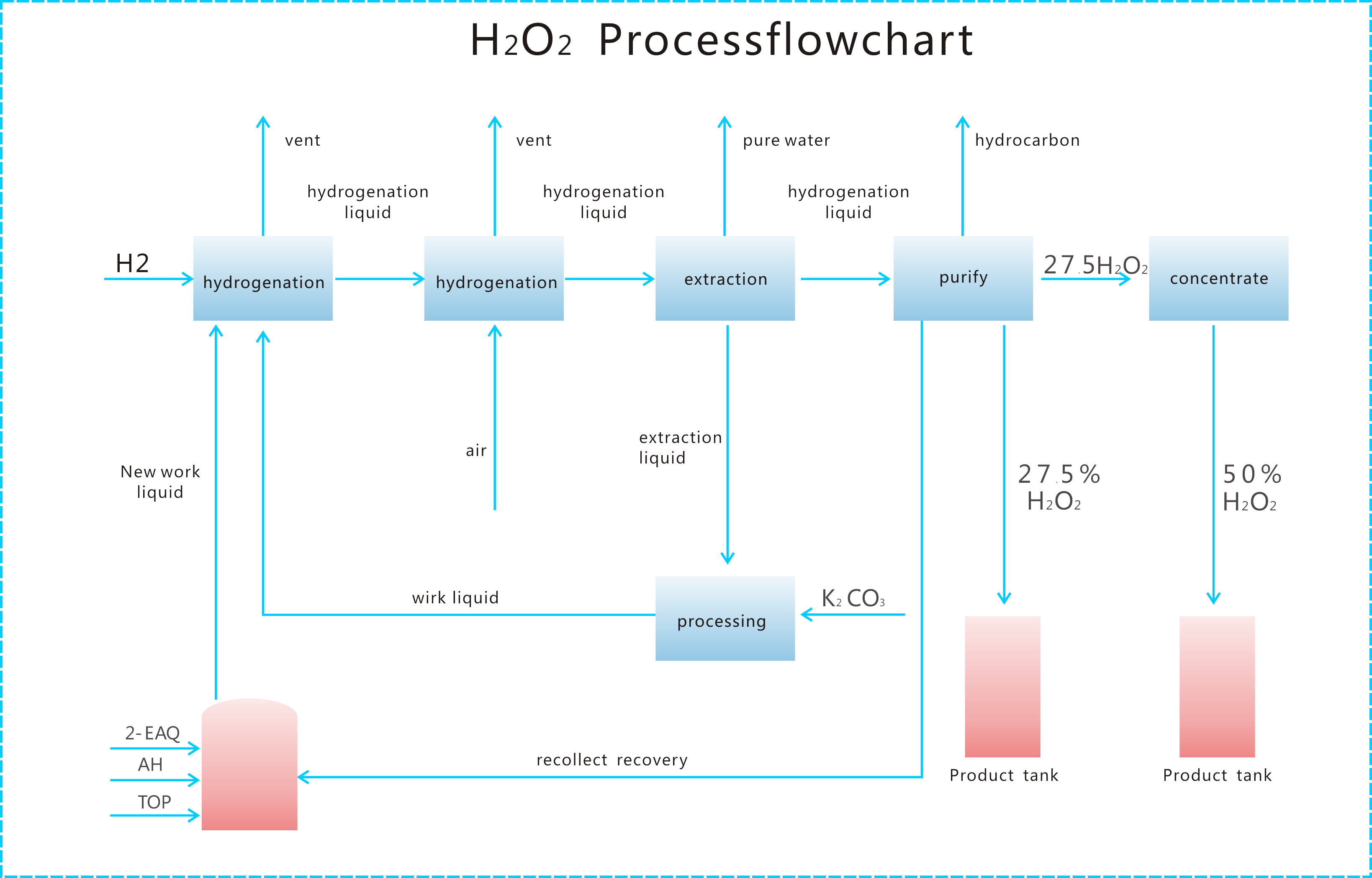

The production of hydrogen peroxide (H2O2) by anthraquinone method is one of the most mature and common production methods in the world. At present, there are 27.5%, 35.0% and 50.0% products in the market in China.

learn more

Characteristic

Technical characteristicsMature technology, short and reasonable process route and low energy consumption.

High degree of automation, safe, simple and reliable operation.

High equipment integration, small on-site installation workload and short construction period.

Process

Technological process

Index

Main performance indicatorsProduct concentration ( w/w ) | 27.5%,35%,50% |

Hydrogen consumption (27.5%) | 195Nm3/t. H2O2 |

Consumption air of H2O2(27.5%) | 1250 Nm3, 2-EAQ: 0.60kg, electricity: 180KWh, steam: 0.05t, pure water: 0.85t |

Unit scale | ≤60MTPD(50%concentration)(20000MTPA) |

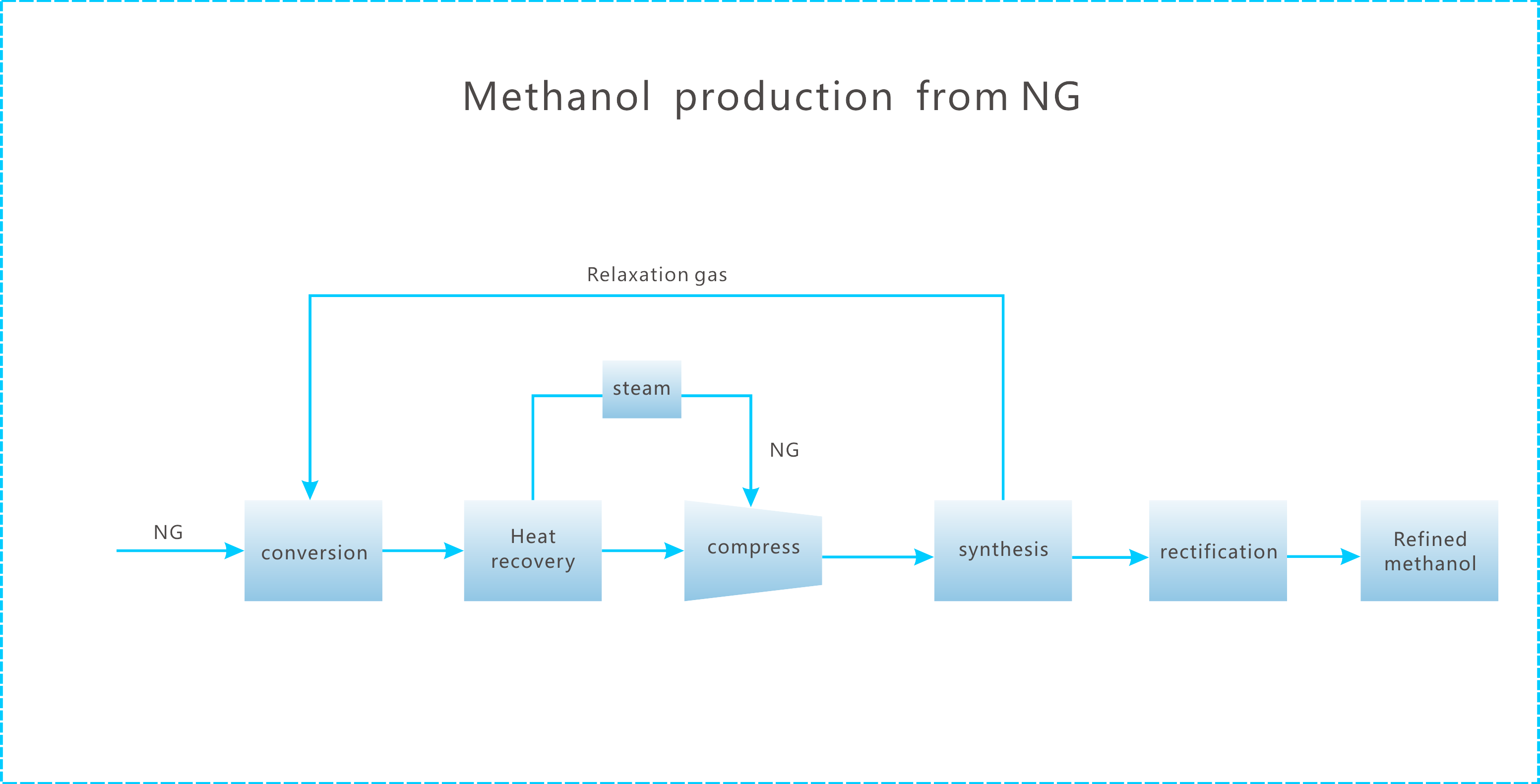

The raw materials for methanol production can be natural gas, coke oven gas, coal, residual oil, naphtha, acetylene tail gas or other waste gas containing hydrogen and carbon monoxide. Since the 1950s, natural gas has gradually become the main raw material for methanol synthesis. At present, more than 90% of the plants in the world use natural gas as the raw material. Because the process of methanol production from natural gas is short, investment is low, production costs are low, and the emissions of three wastes are low, it is a vigorously promoted clean energy.

learn more

Characteristic

Technical characteristicsEnergy saving and investment saving.

High equipment integration, small on-site workload and short construction period.

The methanol synthesis tower with new by-product medium-pressure steam is adopted to reduce energy consumption.

Adopt energy-saving technologies, such as hydrogen recovery technology, pre-conversion, natural gas saturation technology, combustion air preheating technology, to reduce methanol consumption. Through various measures, the energy consumption per ton of methanol was reduced from 38~40GJ to 29~33GJ.

Process

Technological processNatural gas is used as raw material to obtain syngas (mainly H2 and CO) through compression, desulfurization, purification and gas making. The syngas is further compressed and then enters the methanol synthesis tower to synthesize methanol under the action of catalyst. After the synthesis of crude methanol, the fusel is removed by pre-rectification, and the finished methanol is obtained by rectification.

Index

Main performance indicatorsDevice scale | ≤300MTPD (100000MTPA) |

Purity | ~99.90% (v/v) ,conforming to GB338-2011 and O-M-23K AA |

pressure | Normal pressure |

Temperature | ~30˚C |

Use natural gas, coke oven gas, acetylene tail gas or other sources containing rich hydrogen as raw materials to build small and medium-sized synthetic ammonia plants. It has the characteristics of short process flow, low investment, low production cost and low discharge of three wastes, and is a production and construction mode of synthetic ammonia that can be vigorously promoted.

learn more

Characteristic

Technical characteristicsInvestment province. The investment of using natural gas as raw material can be reduced by 50% compared with that of using solid as raw material.

Energy-saving, fully recover the heat of the system. Main power equipment can be driven by steam to realize comprehensive utilization of heat energy.

Adopt energy-saving technologies, such as hydrogen recovery technology, pre-conversion, combustion air preheating technology, to reduce production costs.

Process

Technological processNatural gas is used as raw material, which is compressed, desulfurized, purified, transformed, purified by hydrogen, and added with nitrogen to produce a certain amount of synthetic gas (mainly composed of H2 and N2). After the syngas is further compressed, it enters the ammonia synthesis tower, where ammonia is synthesized under the action of catalyst, and finally the product ammonia is obtained after cooling.

Index

Main performance indicatorsDevice scale | ≤150MTPD (50000MTPA) |

Purity | 99%~99.90% (v/v), in accordance with GB536-2017 |

pressure | Normal pressure |