Water electrolysis hydrogen production is widely used in industrial, commercial and civil fields due to its flexible application site, high product purity, large operation flexibility, simple equipment and high degree of automation. In response to the country's low carbon and green energy, water electrolysis hydrogen production is widely distributed in photovoltaic, wind power and other green power sites.

learn more

Characteristic

Technical characteristicsThe sealing gasket adopts new polymer material to ensure the sealing of the electrolytic cell.

The electrolyzer with asbestos-free diaphragm cloth has the advantages of reducing energy consumption, green environmental protection, no carcinogens, and no need to clean the filter.

Perfect interlocking alarm function.

It adopts independent PLC control and fault self-recovery function.

Small area, compact equipment layout.

Stable operation, continuous operation throughout the year without stopping.

With high automation level, it can realize unmanned management of the device site.

Under the flow rate of 20% - 120%, the load can be adjusted freely, safely and stably.

The equipment has long service life and high reliability.

Index

Main performance indicatorsDevice scale | 50~1500Nm³/h |

Purity | 99.5%~99.999% (v/v) |

Pressure | ≤3.0MPa (G) |

Application

application areaPower, electronics, polysilicon, nonferrous metals, petrochemical, glass and other industries.

Methanol conversion to hydrogen has the advantages of low investment, no pollution and moderate production cost. It is the best technology choice for users who have no reliable source of hydrogen production raw materials and have strong market competitiveness. The methanol conversion hydrogen production technology developed and designed by our company since 2000 has reached the international advanced level. At the same time, we have obtained three national patents and prepared the Technical Requirements for Methanol Conversion PSA Hydrogen Production System (GB/T 34540). The market share of methanol hydrogen production units provided by the world is high, and the scale of a single set reaches 60000 Nm ³/ H. A professional hydrogen production company with a pressure of 3.3MPa and faster catalyst development and update (the sixth generation).

learn more

Characteristic

Technical characteristicsLow energy consumption and low product cost.

Mature technology, safe and reliable operation.

PSA desorbed gas can be completely burned back without environmental pollution.

The raw materials are easily available, convenient for transportation and storage, and the price is stable.

The process is simple, the land occupation is small, the investment is low, and the payback period is short.

The device has high degree of automation, simple operation and can be unattended (only for overseas projects).

Process

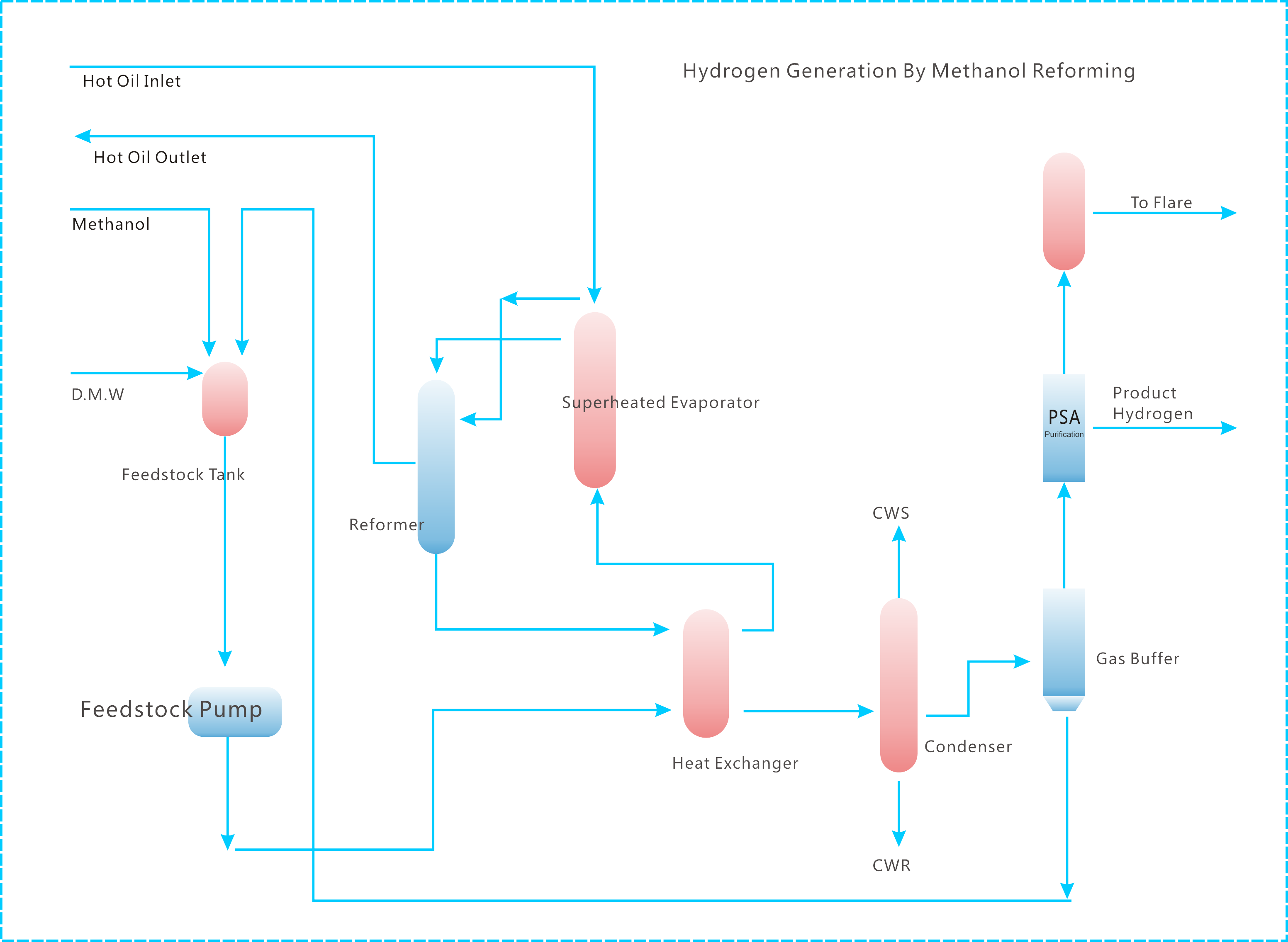

Technological processMethanol and desalted water enter the reactor through mixing, pressurization, vaporization and overheating. Under the action of catalyst, the reaction generates H2, CO2, CO and other mixed gases. The mixed gas is purified or high-purity hydrogen at one time through pressure swing adsorption (PSA) separation technology.

Index

Main performance indicatorsDevice scal | 50~60000Nm³/h |

Purity | 99%~99.9995% (v/v) |

Pressure | 1.0~3.3MPa (G) |

Temperature | Normal temperature |

The bold innovation on the basis of the traditional process has greatly reduced the investment in the unit and the natural gas consumption by about 1/3. Especially in the technical transformation of the natural gas conversion core equipment - the conversion furnace, a breakthrough has been achieved and has been tested on the completed unit. In terms of technological innovation of hydrogen production from natural gas reforming, our company has applied for and obtained six national patents, one American patent and one European Union patent; The small and medium-sized natural gas cylinder furnace hydrogen production system was supported by the Technology Innovation Fund of the Ministry of Science and Technology for small and medium-sized enterprises, and provided 50Nm for the 2008 Beijing Olympic Games ³/ H Natural gas hydrogen production unit.

learn more

Characteristic

Technical characteristicsMature technology, safe and reliable operation.

Simple operation and high degree of automation.

Low operation cost and short payback period.

Low nitrogen emission technology meets environmental protection requirements.

The cylinder furnace structure is optimized, with simple structure and high reliability.

PSA desorption and full reburning can reduce fuel consumption and exhaust emissions.

The device and equipment are highly integrated to realize skidding, with small land occupation, low investment and short construction period.

The boiler circulation system adopts proprietary technology to simplify the process, save investment and reduce consumption.

Wide range of raw materials: natural gas, biogas, LPG, light naphtha, coalbed methane, landfill gas, etc.

Process

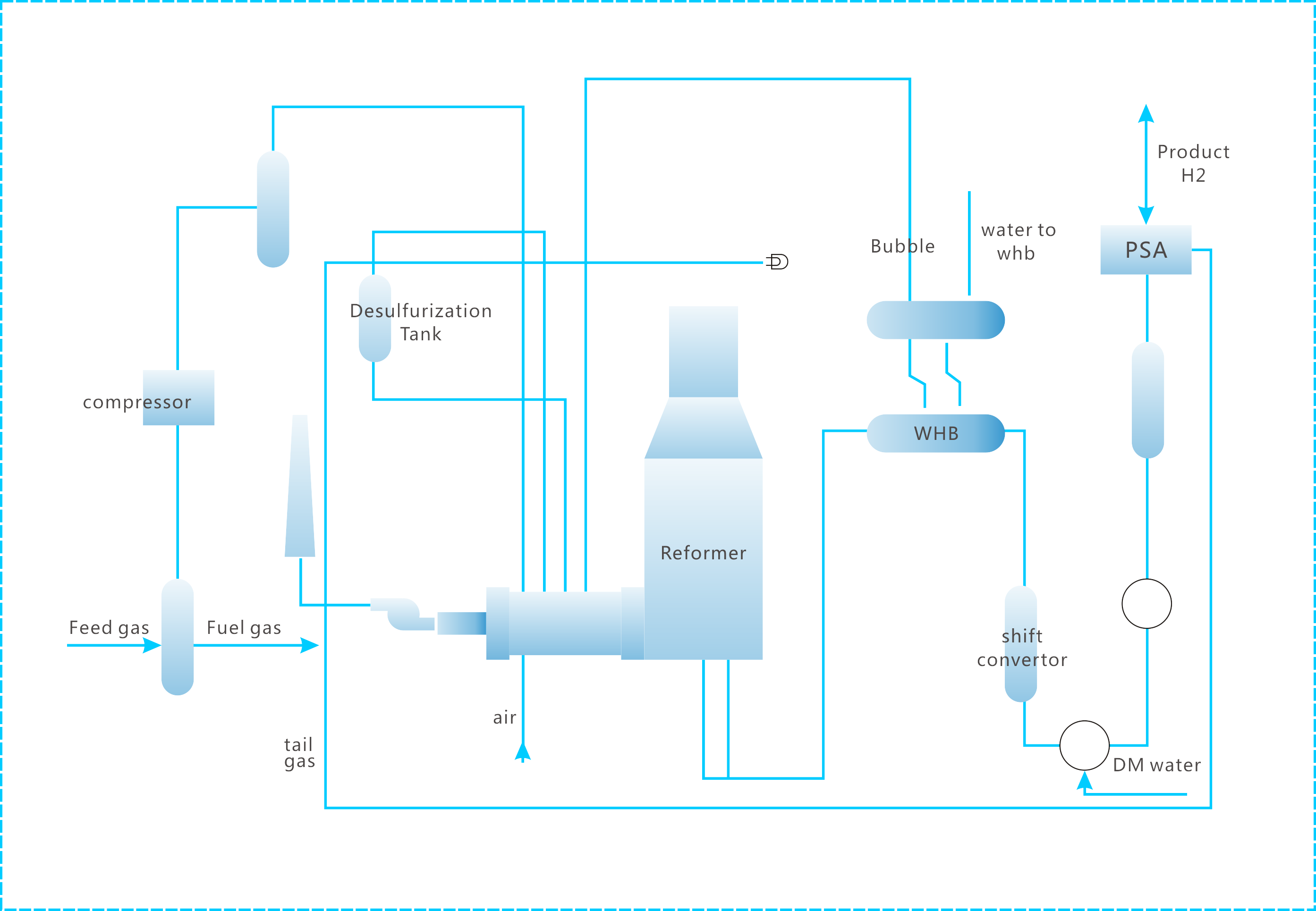

Technological processAfter pressurized desulfurization, natural gas or other raw materials are mixed with water steam and enter the special reformer. Under the action of catalyst, the reformer reacts to produce the reformer gas containing H2, CO2, CO and other components. After the heat of the reformer gas is recovered, CO is converted into hydrogen by the shift reaction. The shift gas is purified by PSA to obtain hydrogen. The PSA tail gas returns to the reformer for combustion and heat recovery.

Index

Main performance indicatorsUnit scale | 50~50000Nm3/h |

Purity | 95%~99.9995% (v/v) |

Pressure | 1.3~3.0Mpa (G) |

Pressure Swing Adsorption (PSA) technology has been widely used in the field of industrial gas separation due to its high automation, simple operation and good environment. Through years of research, test and operation of pressure swing adsorption, a complete set of hydrogen purification technologies in various hydrogen-rich gas sources has been developed to provide customers with upgrading services.

learn more

Characteristic

Technical characteristicsSmall area, compact equipment layout.

With high automation level, it can realize unmanned management of the device site.

Stable operation, online maintenance, continuous operation throughout the year without stopping.

Under 30% - 100% flow rate, the load can be adjusted freely, safely and stably.

The adsorbent data comes from our company's proprietary adsorbent manual, and the data in the manual comes from the evaluation results of our company's special testing instruments.

The pneumatic flat program control valve, the key component of PSA produced by our company, is small in size, light in weight, fast in action, good in sealing performance, long in service life and high in reliability.

Process

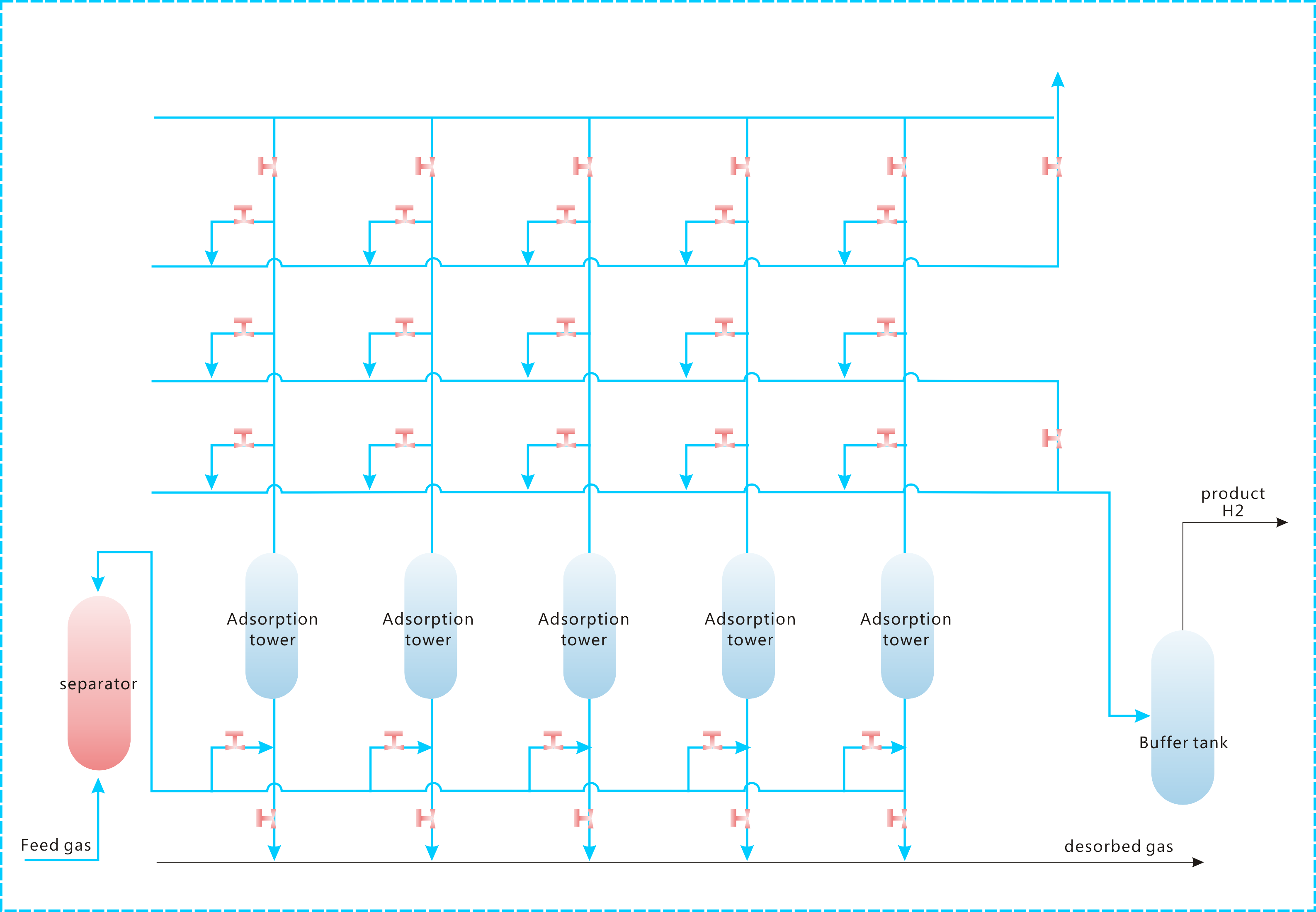

Technological processMulti-tower PSA technology is adopted for hydrogen purification. The working steps are divided into adsorption, pressure reduction, analysis, pressure rise, etc. The adsorption towers are staggered in the working steps to form a closed loop to ensure continuous input of raw materials and continuous output of products.

Index

Main performance indicatorsUnit scale | 10~300000Nm3/h |

Purity | 99%~99.9995% (v/v) |

Pressure | 0.4~5.0Mpa (G) |

Application

application areaPurify hydrogen from shift gas.

Purify hydrogen from chlor-alkali tail gas.

Purify hydrogen from other hydrogen-rich gas sources.

Hydrogen is purified from methanol conversion gas and ammonia cracking gas.

Purify hydrogen from water gas, semi-water gas and coal gasification purified gas.

Hydrogen is purified from styrene tail gas, refinery reforming gas, refinery dry gas, synthetic ammonia or methanol purge gas, and coke oven gas.