Coke oven gas contains impurities such as tar, naphthalene, benzene, inorganic sulfur and organic sulfur. In order to make full use of the coke oven gas, purify the coke oven gas, reduce the impurity content in the coke oven gas, the combustion emission can meet the environmental protection requirements, and can be used as raw materials for chemical production. The technology is mature and widely used in power plants and coal chemical industry.

learn more

Characteristic

Technical characteristicsLeading technology

High purity

Large processing scale

Process

Technological processPurified gas is prepared from coke oven gas after tar removal, naphthalene removal, benzene removal, atmospheric (pressurized) desulfurization and fine desulfurization.

Index

Main performance indicatorsCoke oven gas processing capacity | 1000~460000Nm³/h |

Naphthalene content of refined gas | ≤ 1mg/Nm³ |

Refined gas tar content | ≤ 1mg/Nm³ |

Sulfur content of refined gas | ≤ 0.1mg/Nm³ |

Biogas is an environmentally friendly, clean and cheap combustible gas produced by microorganisms in anaerobic environment, such as livestock manure, agricultural waste, industrial organic waste, domestic sewage and municipal domestic waste, and its main components are methane, carbon dioxide and hydrogen sulfide. Biogas is mainly purified and used for urban gas, vehicle fuel, hydrogen production, etc.

learn more

Characteristic

Technical characteristicsMature technology, safe and reliable.

Low energy consumption and low product cost.

Small land occupation, low investment and short payback period.

The treatment scale is flexible, and the methane recovery rate and purity are high.

The process is simple, the operation is convenient, and the degree of automation control is high.

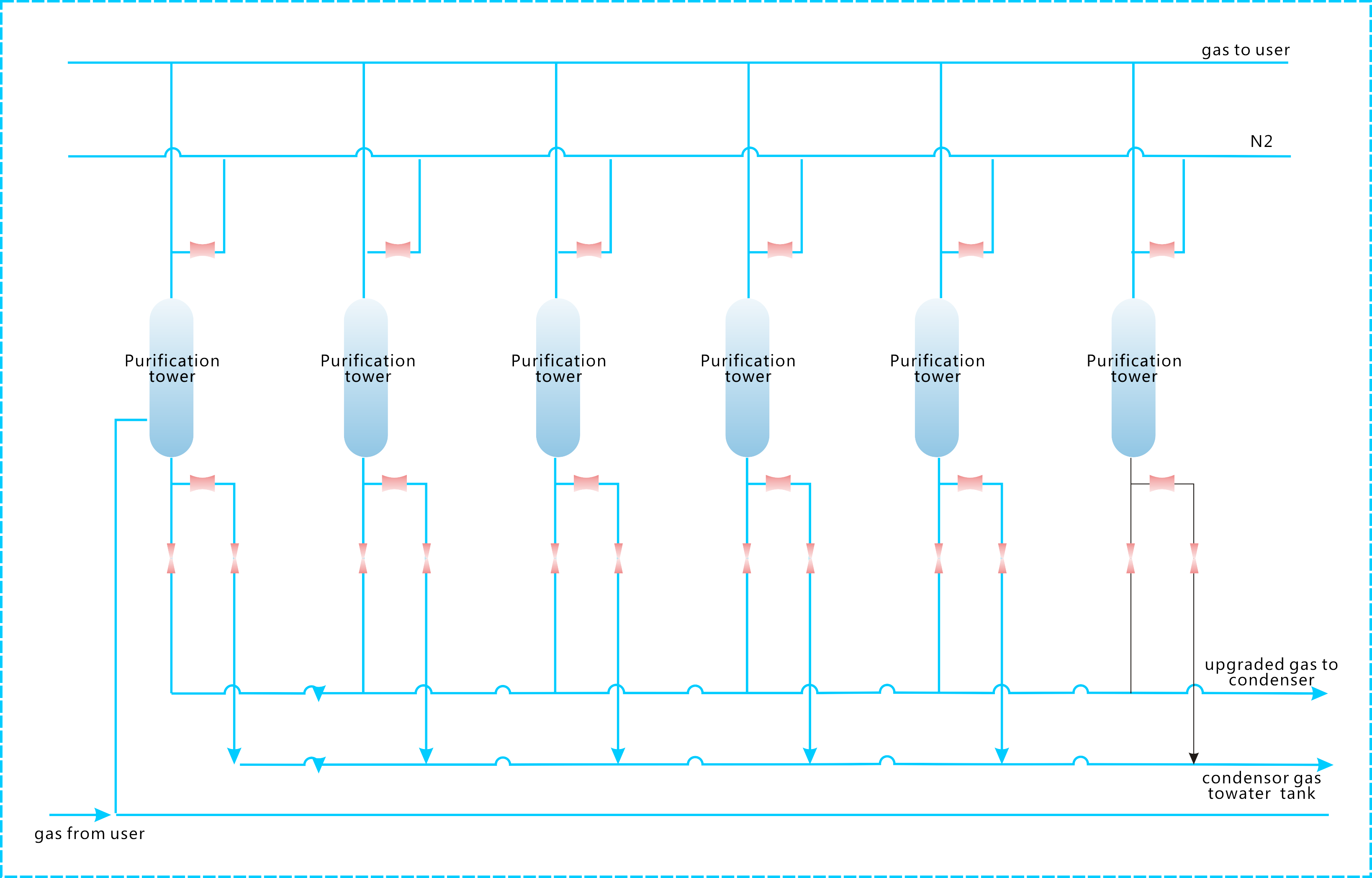

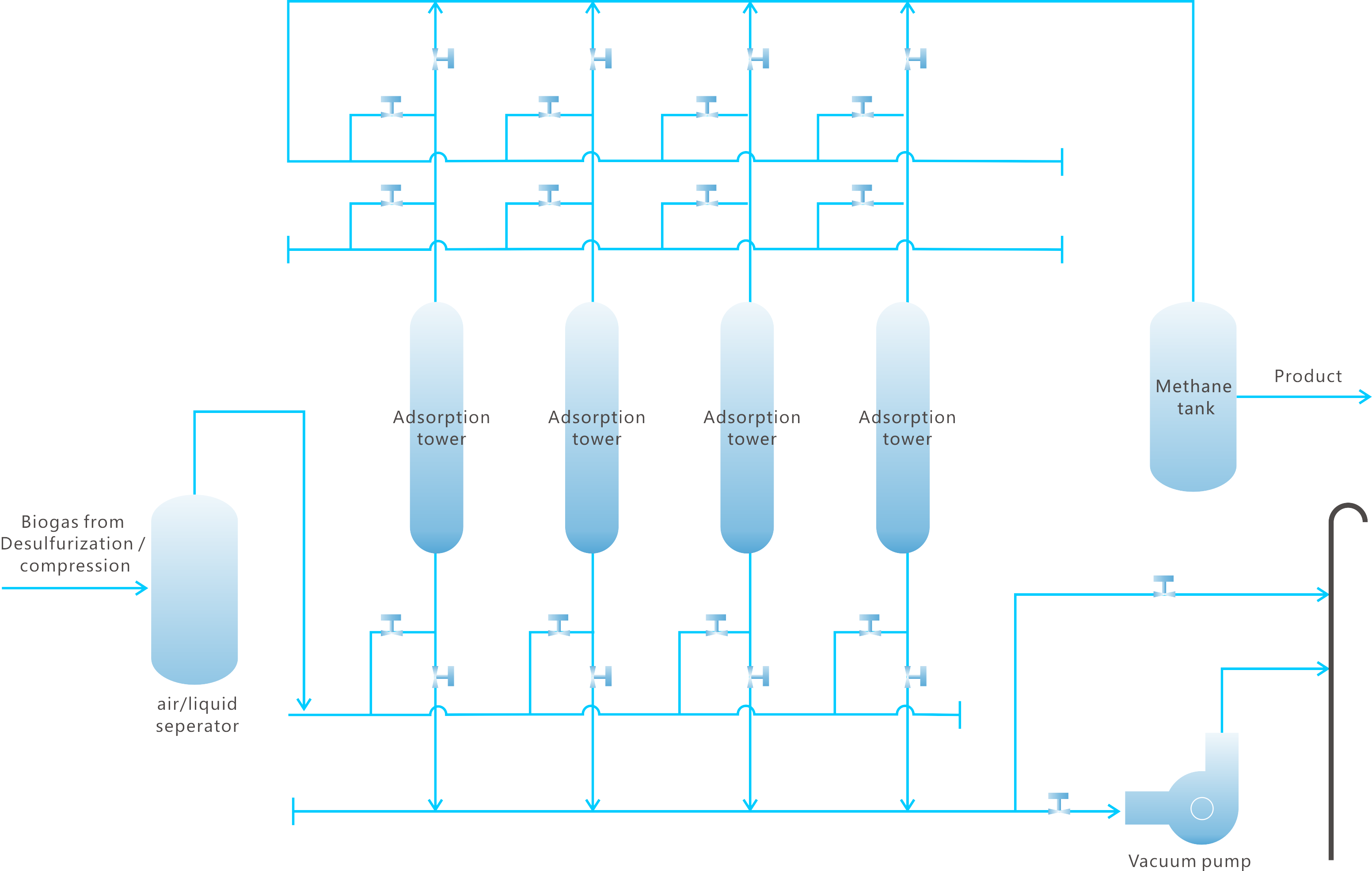

Process

Technological processThe biogas is desulfurized and compressed, pressurized, and then decarburized and purified by pressure swing adsorption (PSA) to obtain product gas.

Index

Main performance indicatorsUnit scale | 50~20000 Nm3/h |

Purity | CH4≥93% |

Pressure | 0.3~3.0Mpa (G) |

Methane recovery rate of product | ≥93% |

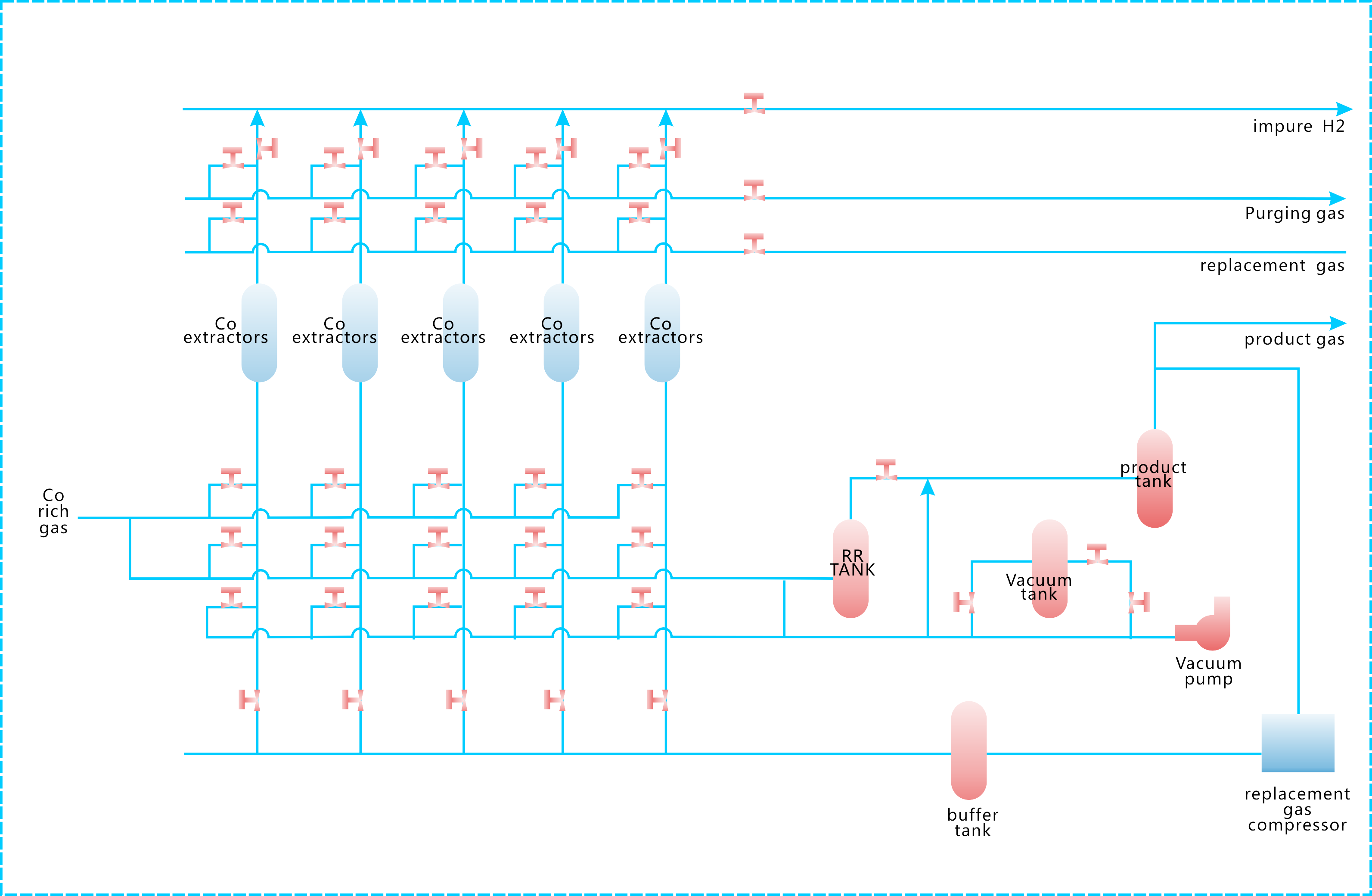

Purify CO with PSA technology and obtain product CO from desorption phase; The adsorbent for purifying CO is developed by our company. It has large adsorption capacity, high selectivity, simple process, high purity and high yield of CO.

learn more

Process

Technological process

Index

Main performance indicatorsUnit scale | 5~3000Nm3/h |

Purity | 98~99.5% (v/v) |

Pressure | 0.03~1.0MPa (G) |

Application

application areaCarbon monoxide is purified from blast furnace gas.

Carbon monoxide is purified from yellow phosphorus tail gas.

Carbon monoxide is purified from the tail gas of calcium carbide furnace.

Purify carbon monoxide from methanol cracking gas.

Carbon monoxide is purified from water gas and semi-water gas.

Purify carbon monoxide from other sources rich in carbon monoxide.

CO2 is the main by-product produced in the industrial production process and has high commercial value. The concentration of carbon dioxide in the wet decarbonization gas can reach more than 99% (dry gas), and the content of other impurities are: water, hydrogen, etc. After purification, it can reach food-grade liquid CO2. Food grade CO2 can be recovered from CO2 rich gases such as natural gas reforming gas, methanol cracking gas, lime kiln gas, flue gas, synthetic ammonia decarbonization tail gas, etc.

learn more

Characteristic

Technical characteristicsMature technology, safe and reliable operation and high yield.

The operation control is reliable and practical.

Process

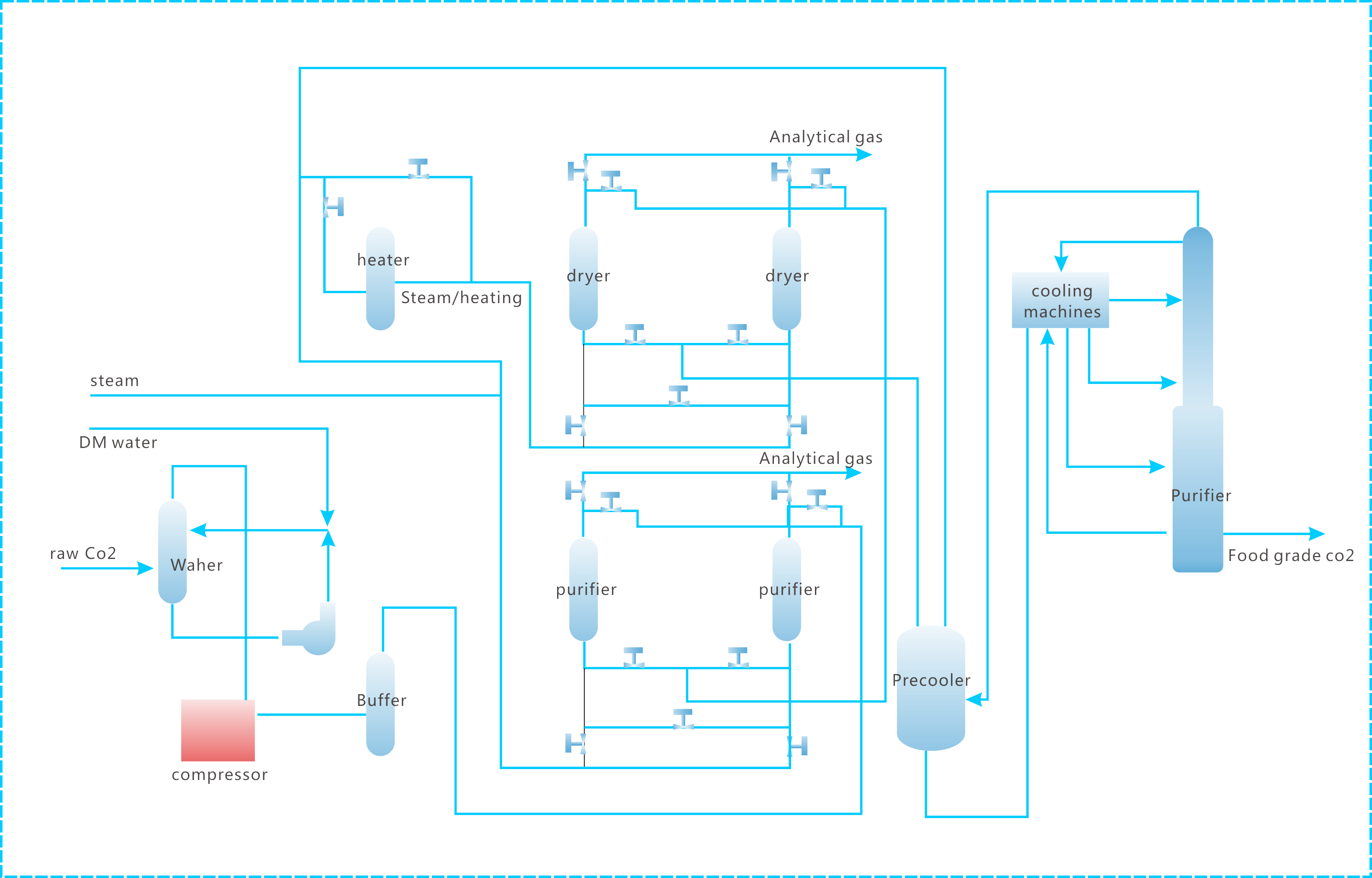

Technological processThe MDEA residue in the feed gas is removed after the raw material is washed with water, and then compressed, purified and dried to remove trace organic substances such as alcohol in the gas and remove the odor. After distillation and purification, the trace low boiling point gas dissolved in CO2 is further removed, and high-purity food-grade CO2 is obtained and sent to the storage tank or filled.

Index

Main performance indicatorsUnit scale | 1000~100000t/a |

Purity | 98%~99.9% (v/v) |

Pressure | ~2.5MPa (G) |

Temperature | ~ -15˚C |

Application

application areaPurify carbon dioxide from wet decarbonization gas.

Remove and purify carbon dioxide from shift gas.

Carbon dioxide is removed and purified from methanol conversion gas.

Carbon dioxide is removed and purified from water gas and semi-water gas.

Remove and purify carbon dioxide from other sources rich in carbon dioxide.

Standard

StandardIt complies with the national standards of GB10621-2006 Liquid Carbon Dioxide for Food Additives, GB1917-94 Liquid Carbon Dioxide for Food Additives (Fermentation Method) and the food grade carbon dioxide standard of Coca-Cola Company.

Wet desulfurization and decarbonization are common gas purification technologies. It is applied in natural gas reforming gas purification, coal gasification combined gas purification, LNG production process with coke oven gas, SNG process. MDEA process is used for H2S and CO2 removal. After purification of syngas: H2S<10mg/Nm ³, CO2<50ppm (LNG process).

learn more

Characteristic

Technical characteristicsMature technology, simple operation, safe and reliable operation.

In natural gas reforming to produce hydrogen, the reboiler does not need external heat source.

Process

Technological processThe synthetic gas enters the reboiler of the regeneration tower at 170 ℃ and is cooled by water after heat exchange. The temperature drops to 40 ℃ and enters the decarbonization tower. The synthetic gas enters from the bottom of the tower, the amine liquid is sprayed from the top, the gas passes through the absorption tower from the bottom to the top, the CO2 in the gas is absorbed, and the decarburized gas goes to the next process for hydrogen extraction, and the CO2 content of the decarburized gas is controlled at 50 ppm~2%. After the amine liquid passes through the decarbonization tower, the lean liquid absorbs CO2 and becomes rich liquid. After exchanging heat with the lean liquid at the outlet of the regeneration tower, it enters the regeneration tower for stripping, and the CO2 gas flows from the tower top to the battery limit. Amine liquid is heated by reboiler at the bottom of the tower to remove CO2 and become lean liquid. The lean liquid flows out from the bottom of the regeneration tower, passes through pressurization, lean and rich liquid heat exchanger and lean liquid cooler for cooling, and returns to the decarbonization tower to absorb the acid gas CO2.

Index

Main performance indicatorsPlant scale | Processing natural gas or shift gas 1000~20000 Nm3/h |

Decarburization accuracy | CO2≤20ppm |

Desulfurization accuracy | H2S≤5ppm |

working pressure | 0.5~15 MPa (G) |

Application

application areaGas purification unit, natural gas hydrogen production unit, etc.